VIBRATORY FINISHING TUB - VKT 300

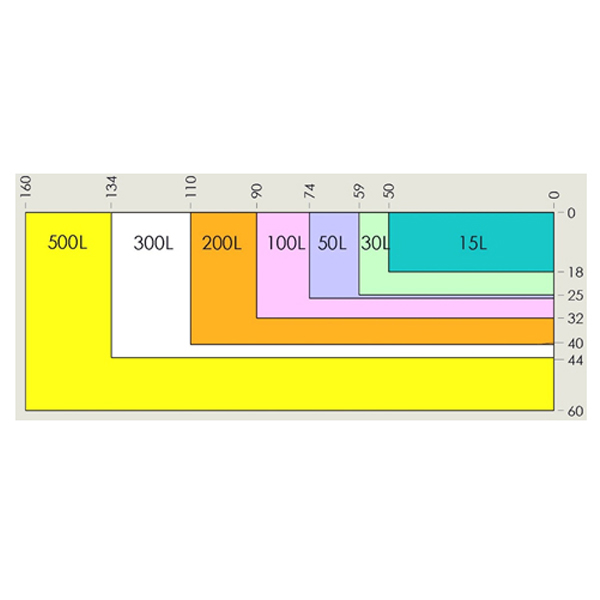

3D300 134cm x 44cm /53" x 17"

Solid and functional design of the VKT 3D300 liters tub finishing machine allows processing of the delicate, thin wall, complex 3D geometries parts. AM/3D metal and plastic parts are successfully deburred, smoothed, or polished in tub - trough machines. All types of tub machines are lined with high quality polyurethane with thickness of up to 25mm. All tub machines are designed to treat single part or multiple parts with use of the dividers - ultimately creating independent compartment for single part process (no part-on-part contact process). MassfinVM - Vibromak tub machines are fitted with different vibratory drive motors/systems depending on their size and processing channel type.

VKT 3D300L U - shaped work channel with straight walls (with single or dual "lip") providing maximum access width for loading and unloading of the components. VKT type machines are driven with one or two motors mounted directly to the processing channel/bowl. This type of drive allows for compact, space saving machine design. Machine is offered with motor VFD, pneumatically powered sound cover, single or multiple drains, auto rotation (CW-CCW), dosing pump, cycle timer, total hour timer...